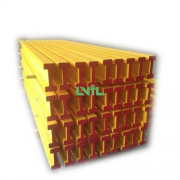

H16 Beam Wood Timber for Construction

With high standardization, universal property, fast...

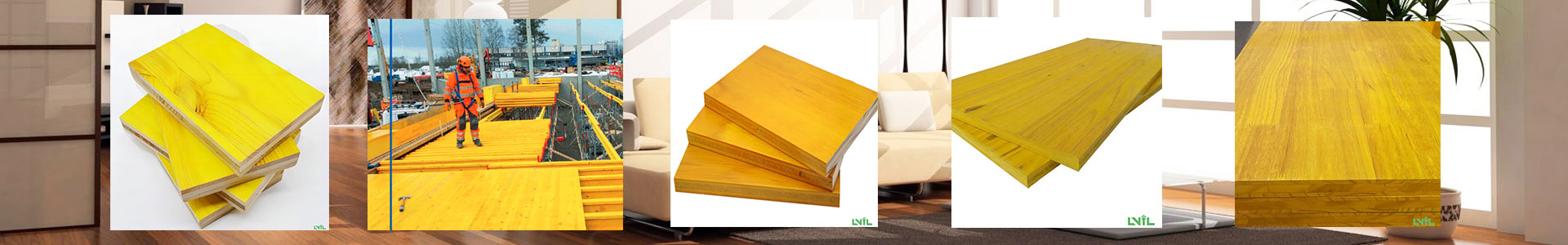

H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

Scaffold H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

- Total 1 Page 3 Records

Key Benefits and Features:

- High Load-Bearing Capacity: The H16 system is designed to handle heavy loads, making it ideal for large-scale and high-strength concrete applications.It can support the weight and pressure of freshly poured concrete, which reduces the risk of formwork failure during the curing process.

- Efficiency and Speed: The H16 formwork system is highly efficient in terms of assembly and disassembly, allowing for faster turnaround times in projects.The modular nature of the system ensures that components can be quickly adapted and configured, reducing overall project timelines.

- Cost-Effectiveness: Its ability to be reused multiple times, coupled with minimal maintenance needs, helps reduce overall costs for contractors.The system’s longevity and ease of use contribute to significant savings on both labor and materials over the life of the formwork.

- Flexibility and Versatility: The H16 formwork system is highly versatile and can be used for a wide range of applications, from foundation walls to columns, slabs, and even complex structural elements.It can be adapted to different geometries and sizes, providing flexibility for various types of construction projects.

- Ease of Handling: Components of the H16 system are designed to be lightweight yet durable, which makes them easier to transport and handle on-site.Its modular design allows workers to assemble and disassemble the formwork system quickly, improving productivity.

- Durability: Constructed from high-strength materials such as steel, the H16 system is built to withstand the pressures and stresses associated with repeated use.The system’s components are resistant to wear and corrosion, ensuring a long service life even under harsh working conditions.

- Safety: The H16 system is designed with safety in mind, incorporating features that ensure the stability and integrity of the formwork during use.Features like secure locking systems, stable frames, and integrated safety components help reduce the risk of accidents or structural failures during the construction process.

- Adaptability to Complex Structures: The system is designed to handle more complex concrete shapes and structures, such as curved walls or uniquely-shaped forms, making it suitable for a wide variety of projects.

- Minimal Maintenance: The H16 formwork system requires little maintenance, which is a major benefit in terms of reducing long-term costs and effort for construction teams.

- Modular Construction: The H16 system is based on a modular design, where individual panels, frames, and components can be combined to create custom configurations to fit the needs of any project.This modular approach makes it easy to scale the system for both small and large projects.

- Panel Sizes: H16 typically comes with various panel sizes (including 1200mm and 2400mm panels), allowing flexibility in configuration and making it easier to accommodate different concrete pours.Larger panels can reduce the number of components needed, speeding up assembly time.

- Steel Frames: The formwork is often built with strong steel frames that provide stability and prevent deformation under pressure.The steel construction ensures that the formwork can endure the heavy loads associated with the pouring of concrete.

- Reusability: The H16 system is designed for repeated use in multiple projects. The components are durable and can be reused many times, making it a cost-efficient investment.Reusability also reduces waste, making the H16 system more environmentally friendly compared to disposable formwork options.

- Adjustable Components: Many H16 systems include adjustable components, which allow for modifications to the formwork design as needed during the construction process.This adjustability makes it easier to form different shapes, dimensions, and heights, ensuring that the system remains versatile across projects.

- Surface Finishing: The H16 system is designed to provide high-quality concrete finishes. The surface of the formwork panels can be smooth or textured, depending on the desired finish for the poured concrete.

- Quick Assembly and Disassembly: H16 formwork components are designed for rapid assembly with simple connection methods, reducing labor costs and construction time.Tools such as bolts, pins, or quick-release mechanisms are often used to secure the panels in place, making the entire setup process quicker and easier.

- High-Quality Material Coating: The materials used in the H16 system are often coated to prevent corrosion and improve longevity. Steel components, for example, may have a galvanized or powder-coated finish to ensure they remain rust-resistant.

- Compatible with Other Formwork Systems: The H16 formwork system is often compatible with other modular formwork systems, allowing for greater flexibility when used in combination with other products on the same project.

Common Applications:

- Walls and Foundations: Ideal for vertical concrete pours like foundation walls, retaining walls, and shear walls, H16 offers the strength and flexibility needed for these critical structures.

- Columns: The H16 system can be used for the construction of concrete columns, with its adjustable components allowing for different heights and diameters.

- Slabs and Decks: It can also be adapted to formwork for horizontal pours such as floor slabs, ceilings, and other deck surfaces.

- Bridge Construction: Due to its ability to handle complex geometries and heavy loads, the H16 system is often used in bridge construction for both foundation and superstructure pours.

- Industrial Structures: The system is well-suited for large industrial projects, including warehouses, factories, and infrastructure such as water treatment plants and power stations.