Key Benefits and Features:

- High Load-Bearing Capacity: The H18 system is engineered to handle heavy loads, making it ideal for large-scale construction projects where concrete pours exert significant pressure.Its robust design ensures stability even under the weight of heavy concrete loads during the curing process.

- Efficiency and Speed of Construction: The system is designed for quick assembly and disassembly, reducing downtime between pours and increasing overall project efficiency.Its modular design allows for easy adaptation to various project requirements, contributing to faster construction timelines.

- Cost-Effectiveness: Due to its reusability and low maintenance costs, the H18 formwork system proves to be highly cost-effective over multiple uses.Its durability means fewer replacements, and its design helps reduce labor and material costs, further improving project profitability.

- Flexibility and Versatility: The H18 system can be used in a wide variety of concrete applications, including walls, columns, foundations, slabs, and other structural elements.It is compatible with different shapes and sizes of structures, making it suitable for both standard and complex formwork configurations.

- Durability and Longevity: Constructed from high-quality materials, the H18 system is designed to endure repeated use in harsh conditions, providing a long service life and ensuring long-term reliability.The components are resistant to wear, corrosion, and damage from frequent handling and concrete exposure.

- Safety: The system includes several safety features, such as secure locking mechanisms, ergonomic designs, and stable support frames to ensure both worker and structural safety.The components are designed to minimize risks of accidents during assembly, disassembly, and while the formwork is in use.

- Minimal Maintenance: The H18 formwork system is designed for ease of maintenance, requiring minimal upkeep between uses. The high-quality materials used in the system reduce wear and tear, lowering overall maintenance costs.

- Customizable: The modular components of the H18 system allow for customization according to specific project needs. Panels and frames can be combined and adjusted to accommodate various formwork designs and configurations.

- Environmentally Friendly: As with many modular formwork systems, the H18 system’s reusability helps minimize waste and promotes sustainability in construction by reducing the need for disposable materials.The system is made from durable and recyclable materials, contributing to environmentally friendly practices in the construction industry.

- Modular Design: The H18 formwork system is based on modular panels, frames, and accessories, allowing for flexible assembly. This modularity ensures quick adjustments to the system to suit different concrete pouring configurations.The modular components also make it easier to handle, transport, and store.

- Panel Sizes: The H18 system includes a variety of panel sizes (typically ranging from 1200mm to 2400mm in height and adjustable in width) to accommodate different structural needs.Larger panels reduce the number of components required, increasing efficiency and reducing the assembly time on-site.

- Strong and Lightweight Frames: The H18 system uses lightweight yet durable steel frames, which provide high strength and support while making the panels easy to handle and move around.These frames are engineered to withstand heavy concrete pressures without distorting, ensuring long-term performance.

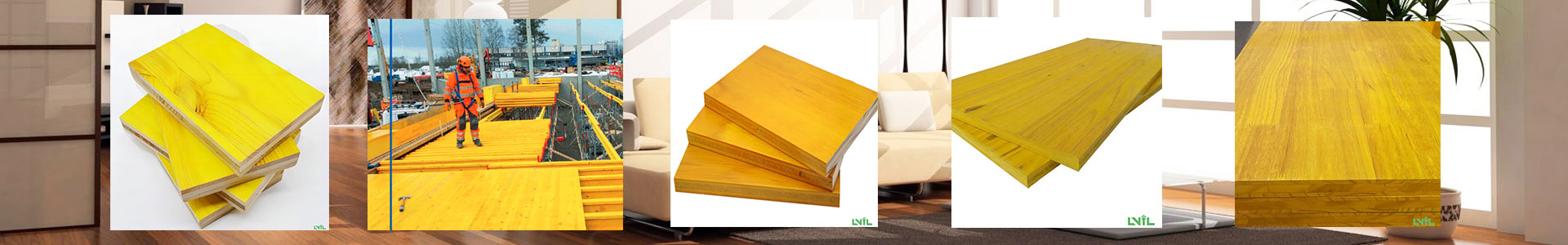

- High-Quality Surface Finishes: The face panels of the H18 system are designed to provide a smooth or textured finish, depending on the project’s requirements.The surface finish is optimized to minimize imperfections in the poured concrete, ensuring the finished structure looks clean and professional.

- Adjustable Components: The system is highly adaptable, featuring adjustable frames, beams, and braces to accommodate different heights, angles, and dimensions. This makes it easier to customize the formwork to fit complex shapes or irregular structures.

- Safety Features: The H18 formwork system incorporates several safety features to protect workers during use. These features include secure locking mechanisms, anti-slip elements, and stable support systems.The system's components are designed to be securely fastened to prevent accidental detachment during concrete pouring or setting.

- Quick Assembly and Disassembly: One of the standout features of the H18 system is its ease of assembly and disassembly. The system is designed for tool-free or minimal-tool use, which saves time and reduces labor costs.Workers can quickly set up the formwork and adapt it to different sections of the project without delays.

- Corrosion and Wear Resistance: The components are often treated with coatings such as galvanization or powder coatings to resist corrosion and extend the life of the formwork system.This resistance to wear and corrosion ensures that the system continues to perform well even in harsh environmental conditions.

- Adaptable to Different Formwork Systems: The H18 system is designed to be compatible with other formwork systems, which allows it to be easily integrated into larger, multi-system projects.This adaptability ensures that H18 can be used in various stages or phases of construction, even if other formwork systems are also in use.

Common Applications:

- Concrete Walls and Foundations: The H18 system is commonly used for vertical formwork, such as walls and foundation elements. It ensures that the structure is strong, stable, and accurately formed.

- Columns: The system is used in the creation of reinforced concrete columns, offering the ability to handle the varied dimensions of column formwork while maintaining the necessary strength.

- Slabs and Decks: H18 formwork can be adapted for horizontal concrete pours like floors, ceilings, and deck surfaces, providing a reliable solution for slab casting.

- Bridges and Infrastructure: The system’s ability to support large, heavy pours and complex shapes makes it ideal for use in bridge construction, as well as other infrastructure projects such as tunnels, dams, and power plants.

- Industrial and Commercial Structures: The H18 system is well-suited for large-scale commercial and industrial buildings, including warehouses, factories, and storage facilities, where strength and efficiency are paramount.

- Precast Concrete Production: The system can be used in the production of precast concrete elements, such as panels, beams, and blocks, providing precision and consistent quality in the manufacturing process.