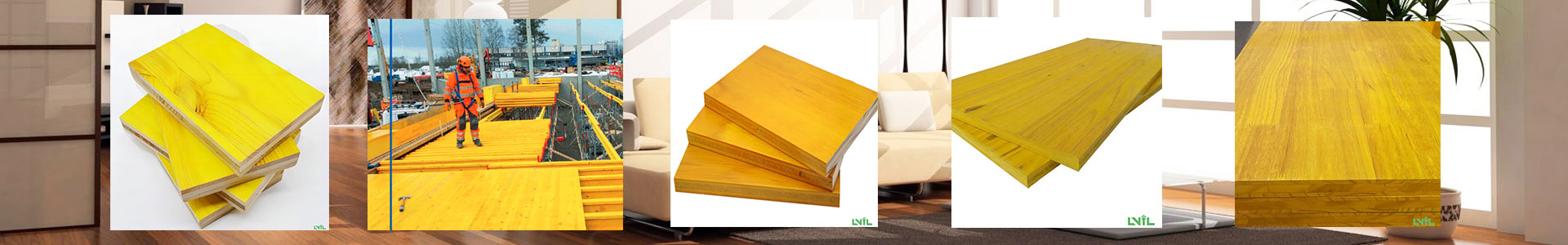

LIVL Formwork Material 3-ply Shuttering Panels Spruce And Fir Wood Three Layer Panels Without Frame

Specifications:

1.Wood type: spruce and red fir

...

Phenolic 3-ply Shuttering Yellow Panels Spruce 21/27mm 3-ply Panels

Customized packaging

Min. order: 1000

Graphic cus...

LVIL 4ftx8ft 3-ply Shuttering Yellow Plywood Waterproof Ply Board 18mm Eucalyptus Plywood 12mm 18mm S

Customized packaging

Min. order: 1000

Graphic cus...

LIVL Pine 3-ply Shuttering Plywood Waterproof Glue Many Times Reuse Yellow Three Ply Boards

Specifications:

1.Wood type: spruce and red fir

...

LVIL formwork plank 3 PLY YELLOW PANEL 3mm -7mm Basswood Plyw

Customized packaging

Min. order: 1000

Graphic cus...

LIVL 27MM 2000X500MM PINE FIR SPRUCE CORE MELAMINE GLUE WBP 3

Specifications:

1.Wood type: spruce and red fir

...

LVIL Comaccord 21mm 27mm Yellow Spruce Core WBP Shuttering Wi

Customized packaging

Min. order: 1000

Graphic cus...

LIVL Formwork 3-ply Shuttering Plywood Spruce/Pine Yellow 3-p

Specifications:

1.Wood type: spruce and red fir

...

LIVL Formwork 21/27mm Spruce 3-ply Panels Concrete Yellow Shu

Specifications:

1.Wood type: spruce and red fir

...

Key Benefits and Features:

- High Strength and Load-Bearing Capacity: 3-ply shuttering panels are designed to withstand the pressure exerted by freshly poured concrete. The cross-laminated construction ensures superior strength and resistance to deformation under heavy loads.

- Smooth Finish: These panels provide a smooth surface finish to the concrete after it is poured and set, which can help reduce the need for additional finishing work once the mold is removed.

- Moisture Resistance: 3-ply shuttering panels are treated with water-resistant adhesives and coatings, ensuring they can endure exposure to moisture and humidity without delaminating or swelling.

- Reusability: Due to their durable construction, 3-ply shuttering panels can be reused multiple times in formwork applications, offering excellent cost-efficiency over time.

- Reduced Shrinkage and Warping: The cross-layered design reduces the risk of dimensional changes, like shrinkage or warping, ensuring the panels retain their shape and performance over multiple uses.

- Lightweight and Easy to Handle: Compared to solid wood or heavier formwork materials, 3-ply shuttering panels are relatively lightweight, making them easier to handle, transport, and assemble on-site.

- Cost-Effective: The ability to reuse the panels and their relatively low cost compared to other formwork materials make them an economical option for construction projects.

- Environmentally Friendly: Made from renewable wood sources, these panels are a more sustainable choice compared to other materials, especially if sourced from responsible forestry practices.

- Material Construction: Typically made from high-quality, durable plywood, 3-ply shuttering panels consist of three layers of veneer with alternating grain directions for enhanced strength and stability.

- Surface Coating: These panels often come with a special resin-based surface coating to enhance their water resistance and improve their performance in harsh construction environments.

- Thickness and Size: Common thicknesses range from 12mm to 18mm, with panel sizes varying depending on the manufacturer’s specifications. Standard sizes are typically 1200mm x 2400mm, but custom dimensions may be available.

- Durability: The panels are designed to handle the abrasion and wear that comes with pouring and setting concrete, which makes them suitable for multiple reuses in the construction industry.

- Surface Texture: The outer face of the shuttering panels is usually smooth or slightly textured to ensure easy release of the concrete once it has set, contributing to a high-quality concrete surface finish.

- Edge Sealing: The edges of the panels are often sealed to prevent moisture absorption and to enhance the longevity and reusability of the panels.

Common Applications:

- Concrete Formwork: Used extensively in the construction of buildings, bridges, roads, and other infrastructure where concrete needs to be poured into a mold and set.

- Slab Casting: Ideal for casting concrete slabs, floors, and walls, particularly where a smooth finish is desired.

- Beam and Column Casting: Suitable for the formwork of beams, columns, and other structural components of concrete buildings.

- Precast Concrete Molds: Can be used in the production of precast concrete components like panels, pipes, and blocks.