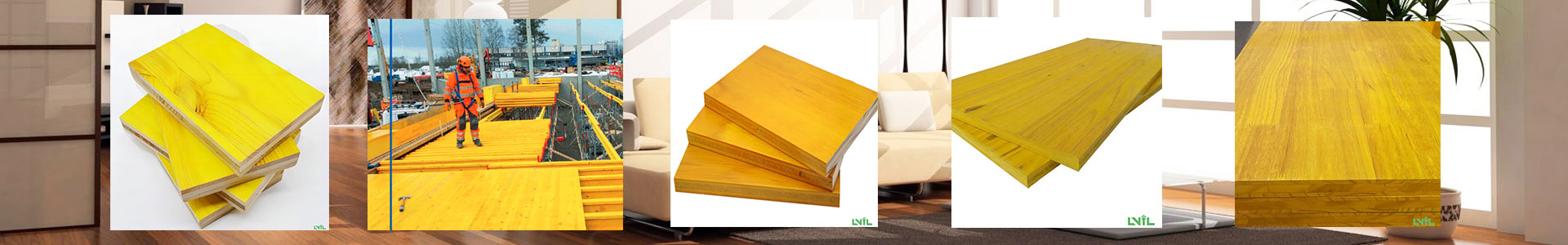

Wood H20 Beam For Building Formwork System

The wooden H beam is a lightweight structural compo...

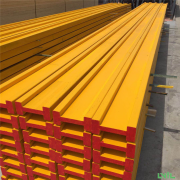

H 20 Prefabricated Formwork Beam

Unique H 20 Prefabricated Formwork Beams are high p...

Unique H20 Timber Beams For Construction

Formwork H20 Timber Beam, also called H20 Wood beam...

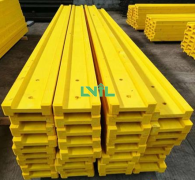

H16 Beam Wood Timber for Construction

With high standardization, universal property, fast...

H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

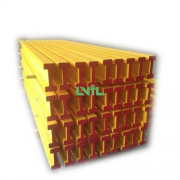

Scaffold H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

H20 Timber Beam

H20 Timber Beam is made from spruce imported from N...

Doka H20 Beam Price

H-20 beam redefine construction with unmatched stre...

Formwork H20 Timber Beam for Sale

Material:Imported Wood(Pine,Spruce,Birch,Fir,Hardwo...

- Total 1 Page 9 Records

Key Benefits and Features:

- High-Quality and Reliable: DOKA is recognized for manufacturing high-quality, durable formwork solutions. Their systems are designed for long-lasting performance, even in demanding environments.

- Flexibility and Versatility: DOKA formwork systems are adaptable to a wide variety of projects, from residential buildings to large-scale infrastructure projects like bridges, tunnels, and dams. The systems are modular and can be customized to fit different shapes and sizes of concrete structures.

- Efficient and Fast Construction: DOKA’s formwork systems are engineered for easy assembly and disassembly, significantly reducing construction time. Their lightweight design and advanced technology improve the speed of concrete pouring and finishing.

- Safety: DOKA systems are designed with safety as a priority. Features such as secure locking mechanisms, stable support structures, and ergonomic handling ensure worker safety on construction sites.

- Cost-Effective: The modular and reusable nature of DOKA formwork helps reduce material costs. The systems are designed to be reused multiple times, which results in lower costs over the course of a project.

- Innovation and Technology: DOKA is known for its commitment to innovation. They incorporate modern technologies in their systems, such as automatic formwork alignment, digital tools for planning, and data analysis for optimization.

- Global Availability and Support: With a strong international presence, DOKA provides support, training, and product availability across the globe. Their teams offer design and engineering support tailored to specific projects.

- Sustainability: DOKA's formwork systems are designed to be reused extensively, minimizing material waste. In addition, many of their products are made from environmentally friendly, recyclable materials.

- Modular Design: DOKA formwork systems are typically modular, meaning they consist of interchangeable panels, beams, and supports that can be easily assembled to meet specific requirements for different structures.

- Wide Range of Applications: The product range includes formwork for walls, slabs, columns, foundations, tunnels, and bridges. Whether for vertical or horizontal concrete pours, DOKA has specialized solutions for every type of concrete structure.

- Ease of Handling: The systems are designed to be lightweight and easy to handle, with ergonomic features that make lifting and moving the components safer and more efficient.

- Cost-Effective Material Usage: Many DOKA systems are optimized for efficient use of materials, reducing wastage and costs, and ensuring the most economical use of formwork resources.

- High Load-Bearing Capacity: DOKA formwork systems are designed to support heavy concrete loads. Their engineering ensures that they can handle the stresses of pouring and setting heavy concrete mixes.

- Surface Finish Options: DOKA offers a variety of formwork surfaces, such as smooth and textured options, to meet the specific finishing requirements of the concrete.

- Robust Construction: DOKA formwork is made from high-strength materials such as steel, aluminum, and high-grade plywood, which can endure the pressure exerted by poured concrete without compromising the integrity of the formwork.

- Adjustable and Modular Components: DOKA systems feature adjustable components, allowing for easy changes in formwork configurations to accommodate different structural requirements. The modular nature means that parts can be reused across various projects.

Common Applications:

- Residential and Commercial Buildings: Used in the construction of walls, floors, ceilings, and foundations, DOKA formwork helps create reliable and efficient concrete structures.

- Infrastructure Projects: DOKA is widely used in the construction of large infrastructure projects, such as bridges, tunnels, and dams, where precision and strength are critical.

- Precast Concrete Production: DOKA provides systems that can be used for the manufacture of precast concrete elements, ensuring high-quality and precise products.

- Industrial Structures: Large industrial facilities, such as factories and warehouses, often use DOKA’s formwork solutions to ensure the construction of durable, large-scale concrete structures.

- Complex Shapes: DOKA offers specialized systems for projects requiring intricate or complex shapes in concrete construction, ensuring flexibility and precision for custom designs.