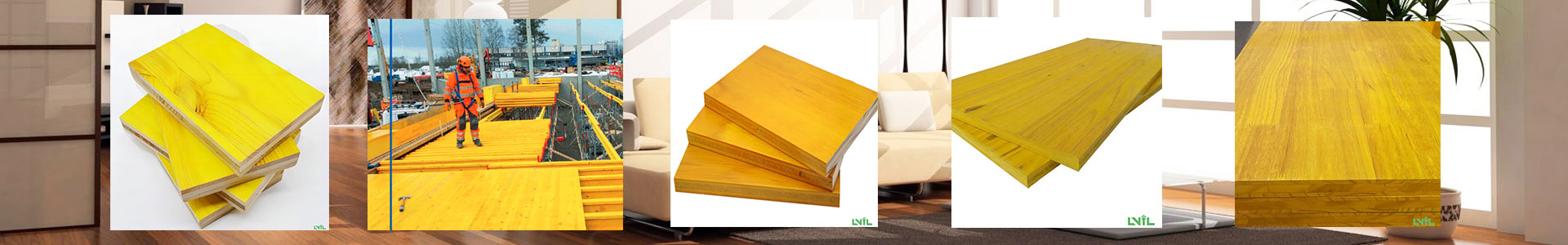

Wood H20 Beam For Building Formwork System

The wooden H beam is a lightweight structural compo...

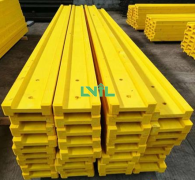

H 20 Prefabricated Formwork Beam

Unique H 20 Prefabricated Formwork Beams are high p...

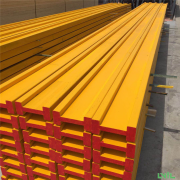

Unique H20 Timber Beams For Construction

Formwork H20 Timber Beam, also called H20 Wood beam...

H20 Timber Beam

H20 Timber Beam is made from spruce imported from N...

Doka H20 Beam Price

H-20 beam redefine construction with unmatched stre...

Formwork H20 Timber Beam for Sale

Material:Imported Wood(Pine,Spruce,Birch,Fir,Hardwo...

- Total 1 Page 6 Records

Key Benefits and Features:

- High Load-Bearing Capacity: H20 beams are engineered to support heavy loads, making them ideal for large concrete pours, such as those required in floor slabs, ceilings, and other structural applications.They are capable of carrying the weight of the formwork panels as well as the freshly poured concrete without bending or deforming.

- Lightweight and Easy to Handle: Despite their high load-bearing capacity, H20 beams are lightweight compared to traditional solid timber beams, making them easier to handle, transport, and install.Their light weight reduces the risk of injury on site and speeds up the assembly process, making labor more efficient and lowering overall costs.

- Cost-Effective: The H20 beam system is reusable, which means it can be used across multiple projects, providing excellent value over time.Because they are durable and require little maintenance, H20 beams help reduce material costs and increase cost-efficiency for contractors.

- Enhanced Durability: H20 beams are made from laminated veneer lumber (LVL) or engineered wood products, which makes them highly resistant to wear, moisture, and weathering.Their longevity ensures they remain reliable and stable through multiple uses and across different concrete pours.

- Versatility: H20 beams are adaptable to a variety of formwork systems, both for vertical and horizontal concrete applications, including slabs, foundations, columns, and ceilings.The modular nature of the system allows H20 beams to be easily adjusted and combined with other formwork components to meet specific project requirements.

- Efficiency in Formwork Assembly: The H20 beams are designed to be easily integrated into formwork systems, reducing the time and effort needed to assemble the formwork on-site.Their straightforward connection methods make the process quicker and more efficient, thus reducing labor costs.

- Sustainability: The use of engineered wood products in H20 beams makes them a more sustainable option compared to traditional solid timber beams.Many H20 beams are made from renewable resources and can be recycled at the end of their service life, promoting environmentally friendly practices in the construction industry.

- Safety: H20 beams are designed to be structurally safe and secure, providing stability during the pouring and setting of concrete.Their engineered design ensures that they perform reliably under heavy loads, reducing the risk of failure during concrete curing.

- Compatibility with Other Formwork Systems: H20 beams are often used in conjunction with other formwork components, such as steel panels, shoring props, and adjustable braces.The system's flexibility allows for seamless integration with other modular formwork components, allowing the system to be adapted for various applications and structural designs.

- Made from Laminated Veneer Lumber (LVL): Laminated veneer lumber (LVL) is a high-performance engineered wood product, made by bonding multiple layers of thin veneer. This makes the beams stronger and more consistent than traditional timber.LVL is lightweight, dimensionally stable, and highly resistant to warping, which ensures the beams perform reliably under heavy loads.

- Standardized Dimensions: H20 beams come in standardized lengths (typically 2.5m, 3m, and 4m lengths, though customizable lengths are also available) and cross-sectional dimensions, making them easy to integrate into various formwork setups.The standardized dimensions allow for greater flexibility in adjusting the beam configuration to fit specific project requirements.

- High Strength-to-Weight Ratio: The H20 beams are designed to be both lightweight and strong, providing a superior strength-to-weight ratio that makes them efficient for use in large concrete pours, while also being easy for workers to manage.This high ratio of strength to weight contributes to faster installation and removal times, improving overall project efficiency.

- Moisture-Resistant and Weather-Resistant: H20 beams are engineered to resist moisture absorption, which is important in construction environments where they might be exposed to wet concrete or variable weather conditions.They are less likely to warp, swell, or deteriorate from environmental exposure compared to traditional timber beams.

- Versatile Compatibility: The beams can be easily combined with other formwork components, such as panels, supports, and props, to create a customized formwork system.The H20 beams can be used in both horizontal (for floor slabs and ceilings) and vertical (for walls and columns) applications.

- Easy Assembly and Disassembly: H20 beams are designed for fast and efficient assembly. Their lightweight nature and modular design ensure that they can be connected and disconnected with ease, saving valuable time during formwork setup and removal.The system’s ease of handling reduces labor intensity, contributing to overall project cost savings.

- Reusability: H20 beams are durable and designed to be reused across multiple construction projects, making them a more cost-effective and sustainable option compared to single-use materials.Their reusability significantly reduces the need for replacements, improving the lifecycle cost of the formwork system.

- High Precision: H20 beams are manufactured to precise specifications, ensuring uniformity and structural reliability across all beams in the system.Their consistent dimensions contribute to the accuracy and stability of the entire formwork system, which is critical for achieving the desired concrete structure.

- Integrated Safety Features: The H20 beam design includes safety features such as secure beam connections and supports that ensure the system remains stable during concrete pours.The design also prevents the risk of premature failure during the curing process, improving overall construction site safety.

Common Applications:

- Concrete Slabs and Floors: H20 beams are widely used in forming horizontal structures, such as concrete floors, ceilings, and other slab forms. The beams provide the necessary support for the weight of poured concrete and any live loads during the curing phase.

- Foundations and Footings: They are commonly used for foundation walls, where they support the formwork for concrete footings and slabs, ensuring precise alignment and a secure structure.

- Beams and Columns: The H20 beam system is used for forming concrete beams and columns, offering a reliable means of ensuring correct form dimensions for these critical structural components.

- Bridge Decks: In bridge construction, H20 beams can be used to form bridge decks and support other parts of the bridge, providing a strong and lightweight solution for these large-scale infrastructure projects.

- Industrial and Commercial Buildings: H20 beams are widely used in industrial and commercial construction, especially for large warehouses, factories, and office buildings, where robust, cost-effective formwork is required.

- Precast Concrete Production: H20 beams are utilized in the creation of precast concrete elements, including slabs, beams, and other structural components, ensuring that each piece is formed accurately and reliably.