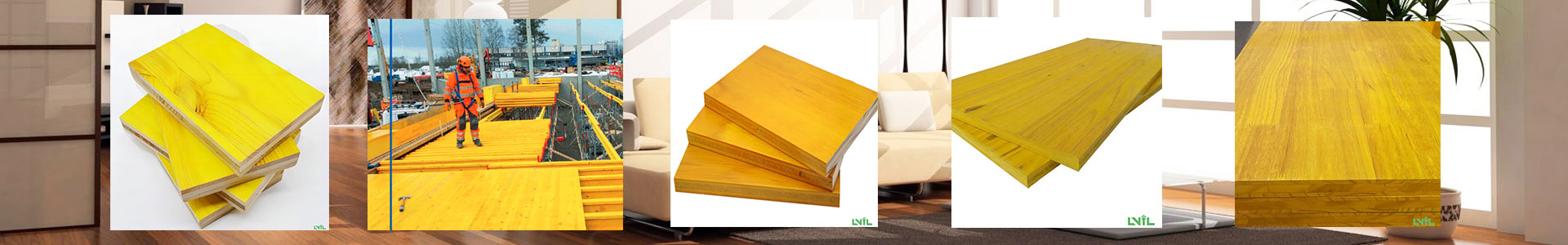

Wood H20 Beam For Building Formwork System

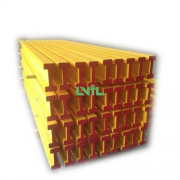

The wooden H beam is a lightweight structural compo...

H 20 Prefabricated Formwork Beam

Unique H 20 Prefabricated Formwork Beams are high p...

Unique H20 Timber Beams For Construction

Formwork H20 Timber Beam, also called H20 Wood beam...

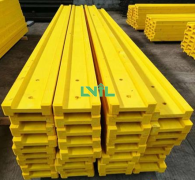

H16 Beam Wood Timber for Construction

With high standardization, universal property, fast...

H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

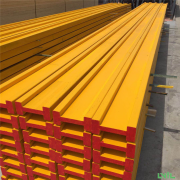

Scaffold H16 Timber Beam for Formwork Construction

H16 Beams are formwork beams made of the highest qu...

H20 Timber Beam

H20 Timber Beam is made from spruce imported from N...

Doka H20 Beam Price

H-20 beam redefine construction with unmatched stre...

Formwork H20 Timber Beam for Sale

Material:Imported Wood(Pine,Spruce,Birch,Fir,Hardwo...

Key Benefits and Features:

- Strength and Durability: The cross-lamination of the layers provides enhanced structural strength, making 3-ply plywood ideal for use in construction and furniture.

- Dimensional Stability: The alternating grain direction reduces the risk of warping or twisting, maintaining its shape over time, even with fluctuations in temperature or humidity.

- Lightweight: Compared to solid wood, 3-ply plywood is lighter, which makes it easier to handle and transport.

- Cost-Effective: It’s generally more affordable than solid wood, providing a cost-effective alternative for many applications while maintaining good strength.

- Versatile: 3-ply plywood can be used for a wide range of projects, including furniture, cabinets, flooring, and structural components in construction.

- Eco-Friendly: Plywood uses thin layers of wood, which can help conserve timber resources as opposed to cutting down large trees for solid wood planks.

- Construction: Made with three thin layers of wood veneer, with the grain of each layer running perpendicular to the one above or below it, offering balanced strength and flexibility.

- Surface Finish: The outer layers (called “face veneers”) are typically higher quality and may be smoother and more uniform, while the inner layers (called “core veneers”) may be rougher and provide structural integrity.

- Thickness Options: Common thicknesses for 3-ply plywood range from 1/4 inch to 3/4 inch, with variations based on the intended use.

- Moisture Resistance: Some types of 3-ply plywood are treated to be resistant to moisture, making them suitable for use in environments with higher humidity (e.g., kitchens, bathrooms).

- Finishing Flexibility: It can be easily sanded, stained, or painted, which allows for a range of aesthetic finishes for interior and exterior use.

Common Applications:

- Cabinets and Furniture: Its combination of strength, lightweight, and cost makes it a popular choice for cabinetry and other furniture items.

- Construction: Used in structural components like floors, roofs, and walls due to its strength and durability.

- Interior Design: Suitable for panels, shelving, and other decorative or functional uses in homes and offices.